Custom Mold Builds

Innovative Ideas call for custom solutions. Custom injection molds bring your inventions to life. Let's get your mold built the right way.

Introducing Olsen Tool & Plastics' Custom Mold Builds

Let us help build the best mold for your manufacturing needs. Our experienced team of mold builders closely examines the intricacies, specifications, and material requirements for every project. Through meticulous attention to detail, we tailor our process to create custom mold builds precisely suited to our customers' needs. We do not take shortcuts. Our step-by-step process ensures consistency and quality that lasts. Our team works together to always take care of you and your molds.

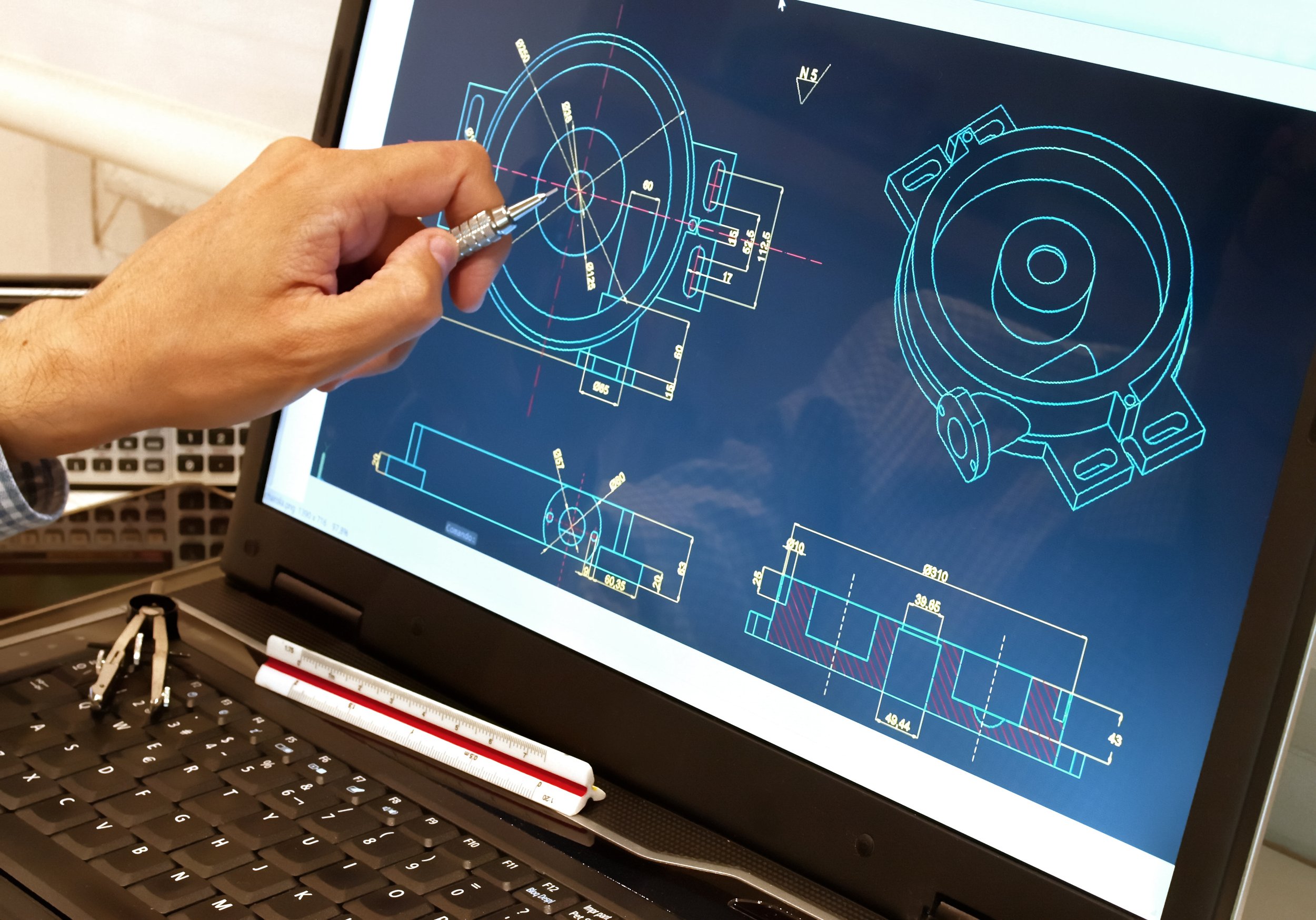

STEP ONEDesign Consulting Services

Olsen Tool & Plastics' team engages early on to identify issues and improve manufacturability. Our experienced toolmakers and in-house tool room provide support for your entire project. From feasibility to design consultation, we work with you to optimize the design to reduce costs and ensure effective production runs.

-

Design assistance for manufacturability and assembly

Working with engineering grade materials

CAD/CAM

Reverse engineering

Material selection

Mold flow analysis

Prototyping

Automation

-

Close tolerance molding

Textured & SPI/SPE finishes

Core pulls

Unscrewing molds

-

SolidWorks

Mastercam

STEP TWOMaterial Selection

We work closely with our customers and suppliers to help you select the best resin for your product’s performance needs and to optimize your mold design and manufacturing processes. We work regularly with a variety of different materials.

-

High Density Polyethylene – HDPE

Low Density Polyethylene - LDPE

Polysulfone - PSU / PPSU

Thermoplastic elastomers - TES / TEO

Polyphenylene sulfide – PPS

Nylon

Polystyrene

Delrin/Acetal

Polycarbonate – PC

ABS

Polypropylene

Acrylic

Polyester – PBT

Glass Filled Compounds

Custom colored resins

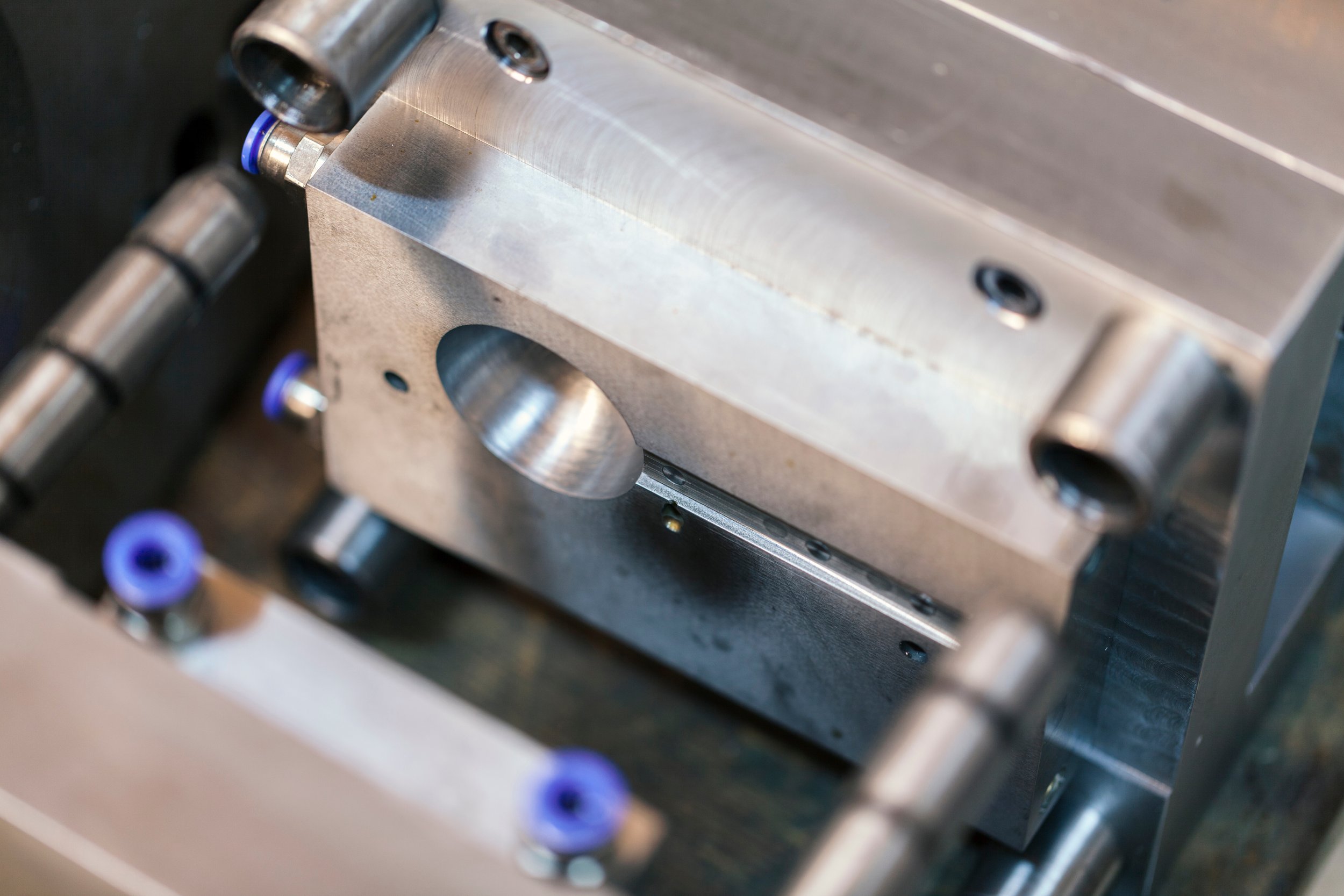

STEP THREEBuild Your Mold

From simple to sophisticated, we build high-quality tools and molds that perform. Our skilled and seasoned tooling team works along side our pressroom personnel to resolve processing issues and to ensure your mold runs at its optimal level. We use only high-quality steel and include safety features, so you can be confident your mold will bring you value for years to come.

To improve your production yield, lower your product cost and meet your quality standards, we are also able to help you design and build any necessary fixtures and gages.

-

Multi-cavity molds

Family molds

Unscrewing molds

Over-molding

Insert molding

Side actions

Lifters

Collapsible cores

Hot manifold & hot tip

Hydraulic and servo-controlled core pull

Mold cavity protection

Revisions & repairs

Changeovers

Gages & fixtures

Robotics assisted manufacturing

STEP FOURRun Your Mold

We have the capacity for large production runs and the agility to meet your short run needs. As a specialist in complex injection molding, we have a variety of presses ranging from 10 to 430 tons and product sizes ranging from miniature up to 37 oz. In addition, with our in-house toolroom and attentive tooling consultants on hand, we can quickly resolve any issues to ensure a seamless production process.

STEP FIVEMaintain, Store, and Transfer

Proper storage of your mold makes a big difference in production yield percentages, maintenance costs, and longevity. With our in-house, multi-step mold maintenance program, we store your molds and keep them in peak condition so they’re ready to run whenever you need them. If you need to transfer your mold to our facility, we regularly help customers manage their inventory and qualification requirements to ensure we keep your production lines running without interruption.

What Makes Us Different

-

In-House Tool Room

Unlike many other manufacturers, we have a full in-house tool room staffed by our experienced toolmakers. Our staff is skilled at helping our customers with design support, feasibility, new mold builds, mold modifications, and repairs.

-

Embracing Creativity

Our doors have been open for over 65 years because we enjoy the challenge of offering creative and cost-saving solutions. We’re not here just to build your mold and run your product. We’re here to optimize it.

-

Years of Expertise

Our seasoned team of manufacturing experts has vast experience with building high-end tooling. Over the years, we have seen it all. We are comfortable and confident in achieving your manufacturing needs.

INTERESTED IN LEARNING MORE?Let's connect. Just fill out the form to start a conversation with us and find out how we can help solve your manufacturing needs. We are excited to hear from you.